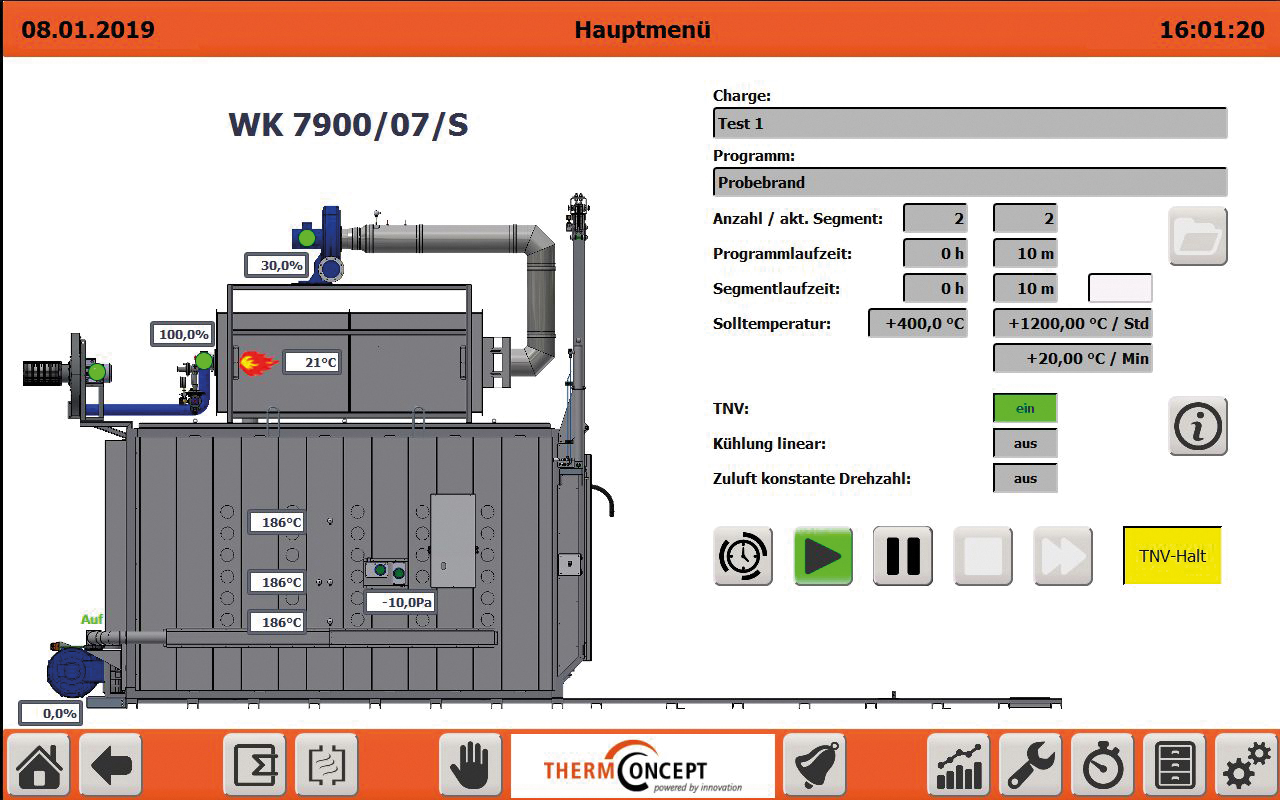

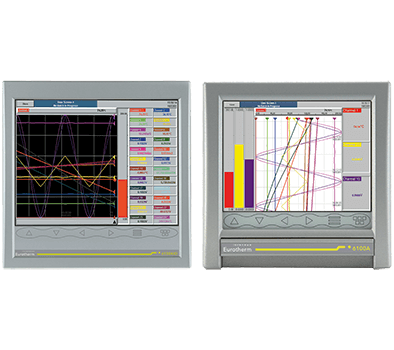

This standard covers requirements for temperature measurement in heat treatment plants of the aerospace industry and concerns furnaces and plants as well as their thermocouples, temperature controllers and displays. The documentation of heat treatment processes as well as regular system accuracy tests and temperature uniformity tests play an important role in quality assurance. These are carried out to ensure that components have been heat-treated in accordance with the applicable standards.

The heat treatment plants are grouped into furnace class (temperature distribution in the useful space) and instrumentation version (pyrometry version).

Temperaturverteilung

Furnace class 1 ±3°C

Furnace class 2 ±6°C

Furnace class 3 ±8°C

Furnace class 4 ±10°C

Furnace class 5 ±14°C

Furnace class 6 ±28°C

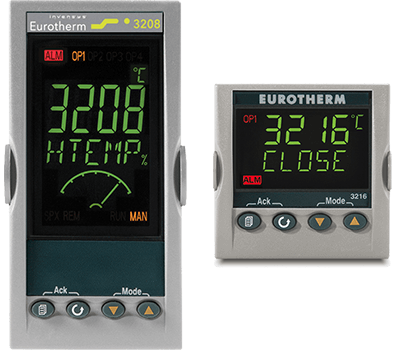

Instrumentierung

Version A

Controller, display, control thermocouples, recorder, overtemperature protection with alarm as well as high & low temperature sensors and min. 1 batch thermocouple

Version B

Controller, display, control thermocouple, recorder, overtemperature protection with alarm and min. 1 batch thermocouple

Version C

Controller, display, control thermocouple, recorder, overtemperature protection with alarm and high & low temperature sensors

Version D

Controller, display, control thermocouple, recorder, overtemperature protection with alarm

Version E

Controller, display, control thermocouple