Techn. ceramics, industrial glass, 3D printing

We have used our decades of experience in these diverse fields of application to offer you sophisticated solutions. Here you will find information for your individual requirements.

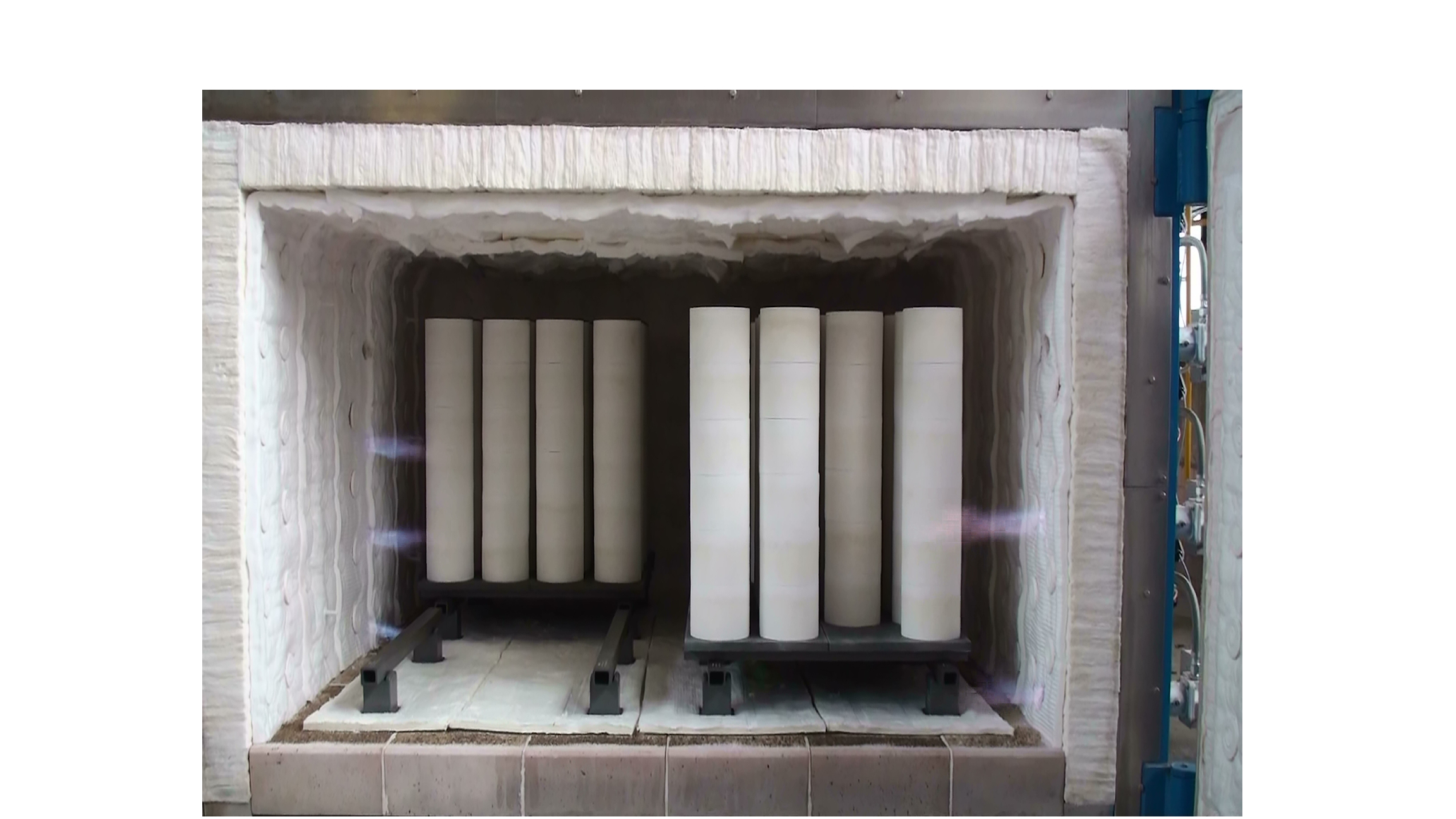

- Sintering

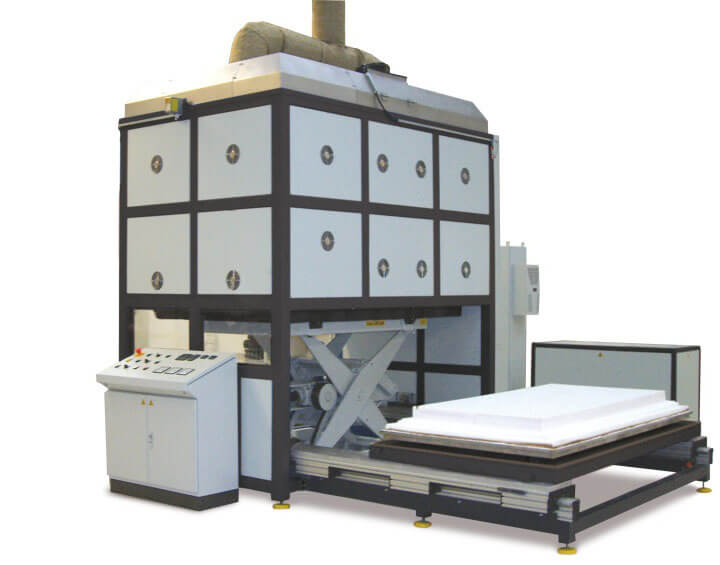

- Debinding

- Firing

- Calcination

- Bending, arching

- Cooling

- Drying

PDF Download:

Furnaces for Ceramics, Glass, Solar