Research & laboratory

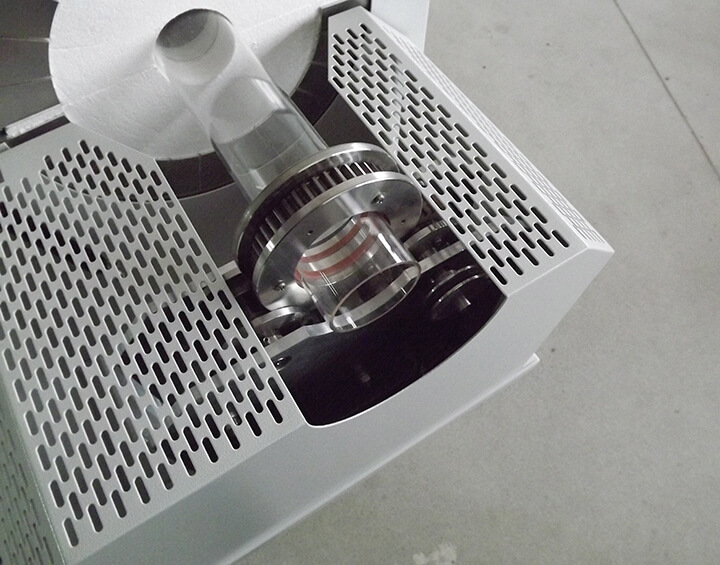

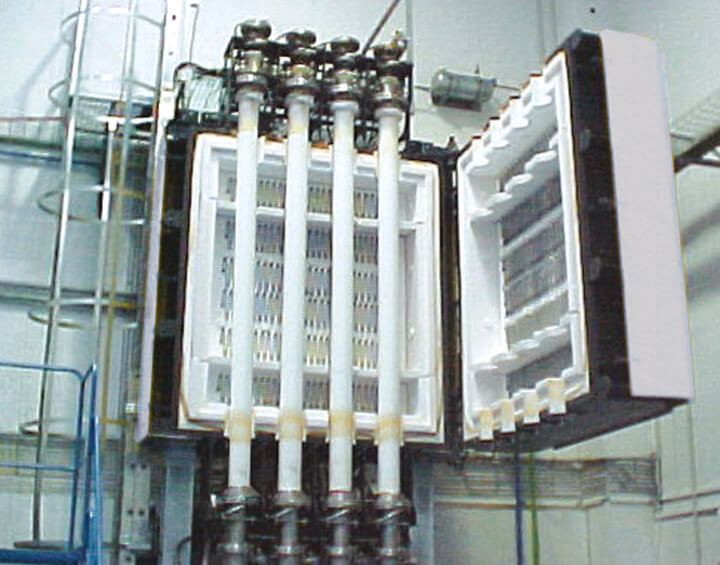

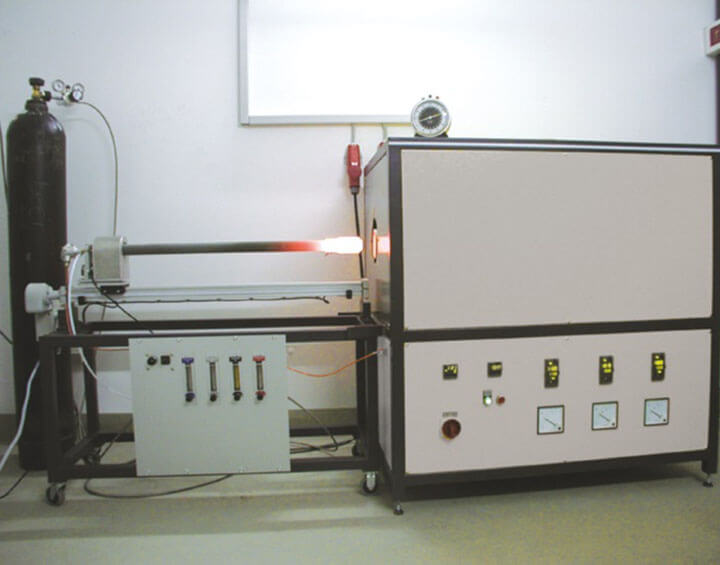

The tasks in modern laboratories are varied and complex. With our extensive range of laboratory furnaces (from drying ovens up to tube furnaces), many applications can be realised, e.g:

- Testing, analysing

- Ashing

- Drying

- Preheating

- Debinding

- Vacuum application

- Sintering

- Annealing

PDF Download:

Laboratory Furnaces